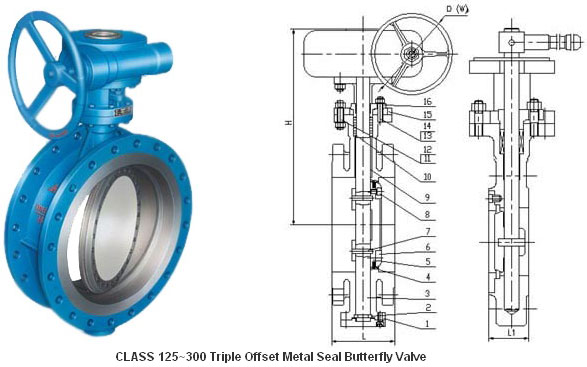

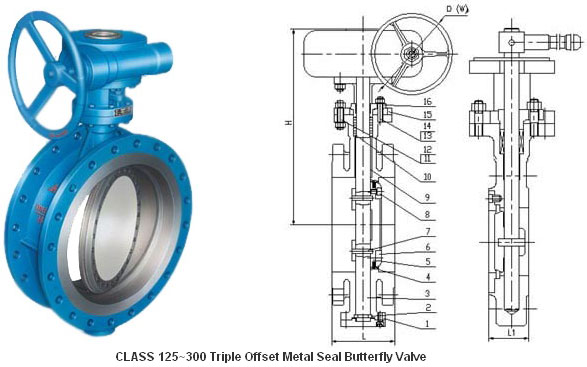

The pneumatic hard seal butterfly valve produced is made up of angular travel pneumatic actuators and three-dimensional braided hard seal butterfly valve. the valve seat adopts a multi-level structure compatible with hard sealing, and is exquisite in processing and advanced in technology. The pneumatic metal seal butterfly valve is matched with the electric valve positioner. the operation can be controlled by inputting 4 - 20m ADC signal and 0.4 - 0.7 MPa air source. the adjustment of pressure, flow rate, temperature, liquid level and other parameters can be realized. The pneumatic hard seal butterfly valve is equipped with a travel limit switch, a solenoid valve, a pressure reducing valve and a 0.4 - 0.7 MPa air source to realize switch operation and send out two pairs of passive contact signals to indicate the switch of the valve. Pneumatic hard seal butterfly valve consists of main components such as valve body, butterfly plate, multi-level valve seat, valve stem, transmission mechanism, etc. it has simple structure, small volume and light weight. therefore, pneumatic hard seal butterfly valve is widely used in pipelines of corrosive media such as metallurgy, electric power, petroleum, chemical industry, air, gas, combustible gas, water supply and drainage, etc.

Characteristics of pneumatic hard seal butterfly valve products

( 1 ) the pneumatic hard seal butterfly valve adopts a three-eccentric sealing structure, with almost no wear between the valve seat and the butterfly plate, and has a sealing function that is more and more tight.

( 2 ) the sealing ring is made of stainless steel, which has the double advantages of hard metal sealing and elastic sealing. no matter at low or high temperature, it has excellent sealing performance, corrosion resistance and long service life.

( 3 ) the butterfly plate sealing surface is made of cobalt-based hard alloy, which is wear-resistant and has long service life.

( 4 ) the large-size butterfly plate adopts a quilting frame structure, which has high strength, large over-flow area and small flow resistance.

( 5 ) the pneumatic hard seal butterfly valve has a bi-directional sealing function and can be installed in any direction without being limited by the flow direction of the medium or the influence of the space position.

( 6 ) the pneumatic device can be installed in multiple stations ( 90 or 180 degrees of rotation ), which is convenient for users to use.

Technical parameters of pneumatic hard seal butterfly valve

| Nominal size DN(mm) |

DN50~1000mm |

Actuator model |

Gt, at, aw series single and double acting pneumatic actuators |

| Nominal pressure ( MPa ) |

PN0.6、1.0、1.6、2.5MPa |

Supply pressure |

0.4~0.7MPa |

| Body form |

Through cast valve body |

Air source interface |

G1/4"、G1/8"、G3/8"、G1/2" |

| Connection form |

Flange type, opposite clip type |

Ambient temperature |

-30~+70℃ |

| Core form |

Butterfly plate |

Action form |

Single-acting actuator, double-acting actuator |

| gasket |

Flexible graphite, PTFE |

Accessory |

Positioner, solenoid valve, air filter pressure reducer,

retaining valve, travel switch, valve position

transmitter, handwheel mechanism, etc. |

| discharge characteristic |

Approximately equal percentage, linearity |

It adopts a new type of pneumatic actuators, with double-acting and single-acting ( spring return ), rack and pinion drive, safe and reliable. Large diameter valves adopt series aw type pneumatic actuators fork-pull transmission, with reasonable structure, large output force, double-acting type and single-acting type.

1. gear type double piston, with large output torque and small volume.

2. the cylinder is made of aluminum-gold material, which is light in weight and beautiful in appearance.

3. manual operating mechanisms can be installed at the top and bottom.

4. rack type connection can adjust opening angle and rated flow.

5. the actuator can select live signal feedback instructions and accessories to realize automatic operation.

6. iso5211 standard connection provides convenience for installation and replacement of products.

7. the adjustable joint screws at both ends can make the standard product have an adjustable range of 4 between 0 and 90. Ensure the synchronization accuracy with the valve. |

| Range of motion |

0~90° |

| Leakage q |

Conform to ansi class b 16.104 iv standard |

| Applicable temperature |

Hard seal ≤ 450 ℃ |

| intrinsic error |

With positioner: less than 2 % of total travel |

| return difference |

With positioner: less than 2 % of total travel |

| adjustable extent |

50:1 |

| Configuration actuator |

Gt, at, aw series single and double acting pneumatic actuators |

| Control mode |

Switch two-position control, 4 - 20ma analog control |

Material of main parts of pneumatic hard seal butterfly valve

| Part name |

Material |

| Body |

Cast iron, stainless steel, chrome molybdenum steel, alloy steel |

| Plate |

Cast steel, alloy steel, stainless steel, chromium molybdenum steel |

| Seal ring |

Stainless steel and high temperature resistant asbestos board are

combined into multiple layers |

| Stem |

2cr13, 1cr13 stainless steel, chromium molybdenum steel |

| Packing |

O - ring, flexible graphite |

Main performance specifications of pneumatic hard seal butterfly valve

| Nominal size DN(mm) |

DN50~1200 |

Nominal

pressure |

PN(MPa) |

0.6 |

1.0 |

1.6 |

2.5 |

Test

pressure |

strength test |

0.9 |

1.5 |

2.4 |

3.75 |

| pressure test |

0.66 |

1.1 |

1.76 |

2.75 |

Low

pressure

airtight test |

0.5~0.7 |

Applicable

medium |

Air, water, sewage, steam, gas, oil, etc |

Applicable

temperature |

Carbon steel: - 29 ℃ ~ 600 ℃ stainless steel: - 40 ℃ ~ 600 ℃ |

Selection of pneumatic hard seal butterfly valve products

( 1 ) valve body parameters: nominal diameter, working pressure, process medium, use occasion, valve body material and other series of parameters.

( 2 ) actuator parameters: actuator form, control mode, control signal ( 4 - 20ma, 1 - 5v ), action mode ( air - open, air - closed )

Try to provide the technical parameters of pneumatic hard seal butterfly valve in detail so as to facilitate our company's operation and technical personnel to select the right type for you. If you have any questions, you can call us and we will do our best to provide you with quality service!

AEN.TECH

AEN.TECH