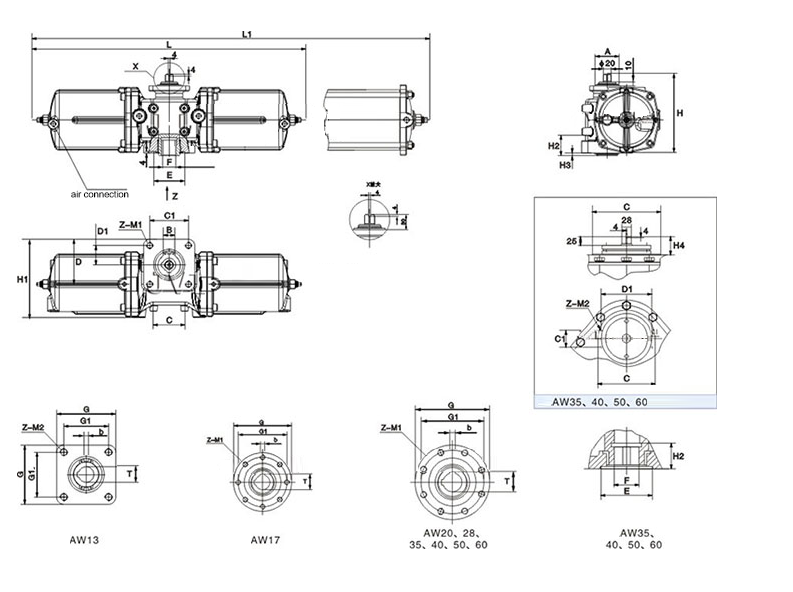

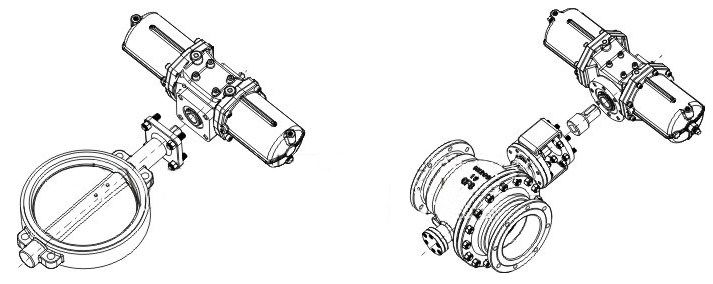

overview of AW pneumatic actuator products

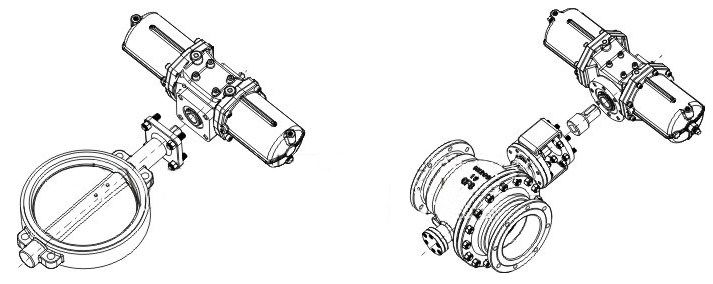

AW pneumatic actuator pneumatic device suitable for turning at 90 DEG C (1/4 RPM) valve. Such as ball valve, butterfly valve, plug valve etc.. This product is designed and manufactured with JIS standard. It is manufactured in accordance with the international standard ISO5211.AW/AW-S pneumatic actuator, and the performance is excellent and the quality is stable.

AW pneumatic actuator model specification

|

Model specification

|

Gas pressure( Mpa )

|

|

0.3

|

0.4

|

0.5

|

0.6

|

0.7

|

|

AW13

|

515

|

620

|

770

|

930

|

1080

|

|

AW17

|

950

|

1270

|

1590

|

1910

|

2230

|

|

AW20

|

2150

|

2870

|

3580

|

4300

|

5020

|

|

AW25

|

3360

|

4480

|

5600

|

6720

|

7850

|

|

AW28

|

5150

|

6860

|

8580

|

10300

|

12020

|

|

AW35

|

10120

|

13500

|

16870

|

20250

|

23620

|

|

AW40

|

13220

|

17630

|

22040

|

26450

|

30860

|

|

AW50

|

22460

|

29950

|

37440

|

44930

|

52420

|

|

AW60

|

47300

|

63070

|

78840

|

94610

|

110380

|

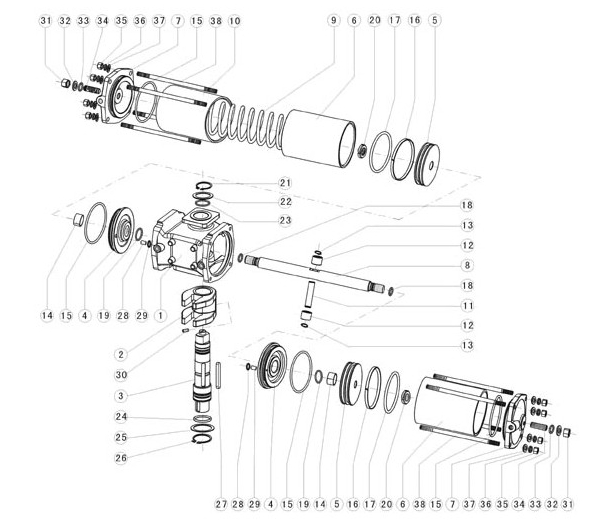

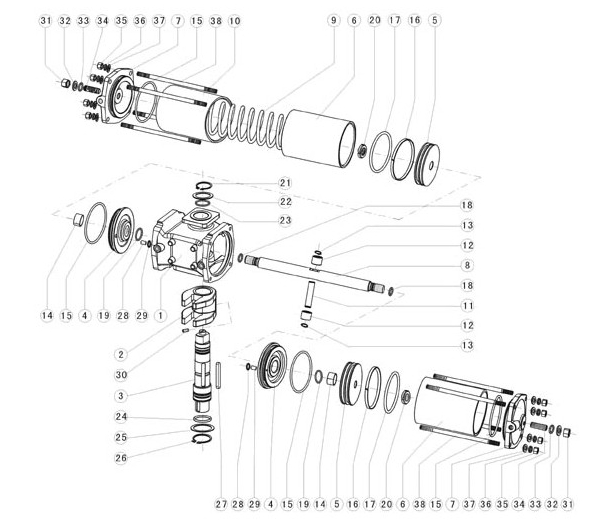

AW pneumatic actuator decomposition diagram

AW pneumatic actuator parts description

|

NO.

|

Name

|

Number

|

Serial number

|

Name

|

Number

|

NO.

|

Name

|

Number

|

NO.

|

Name

|

Number

|

|

1

|

Box

|

1

|

11

|

Pin shaft

|

1

|

21

|

Circlip

|

1

|

31

|

Lock nut

|

2

|

|

2

|

Fork

|

1

|

12

|

Roll sleeve

|

2

|

22

|

Antifriction washer

|

1

|

32

|

Flat washer

|

2

|

|

3

|

Shaft

|

1

|

13

|

Circlip

|

2

|

23

|

O ring

|

1

|

33

|

O ring

|

2

|

|

4

|

A partition

|

2

|

14

|

Oilless bearing

|

2

|

24

|

O ring

|

1

|

34

|

Adjusting screw

|

2

|

|

5

|

Piston

|

2

|

15

|

O ring

|

2

|

25

|

Antifriction washer

|

1

|

35

|

Nut

|

8

|

|

6

|

Cylinder block

|

2/3

|

16

|

Guide ring

|

2

|

26

|

Circlip

|

1

|

36

|

Spring washer

|

8

|

|

7

|

Cylinder head

|

2

|

17

|

O ring

|

2

|

27

|

Flat key

|

1

|

37

|

Flat washer

|

8

|

|

8

|

Piston rod

|

1

|

18

|

O ring

|

2

|

28

|

Oring

|

2

|

38

|

Stud

|

8

|

|

9

|

Spring

|

1/2/4

|

19

|

O ring

|

2

|

29

|

Dowel pin

|

2

|

39

|

|

|

|

10

|

Spring cylinder

|

1

|

20

|

Lock nut

|

2

|

30

|

Set screw

|

1

|

40

|

|

|

AW pneumatic actuator main performance characteristics

1. AW pneumatic actuator is divided into double action, single acting type (spring reset), 2 split cylinders. Easy to manufacture large size cylinder. Meet all kinds of large rotating valve demand.

2. Large output torque, flexible balance cylinder wall and piston shaft with hard chrome plated and has good anti friction property, all moving parts with or without oil lubrication of the shaft and the guide ring to reduce the friction coefficient, prolong the service life of AW pneumatic U type curve of the output torque of the actuator is more suitable for large caliber ball valve, butterfly valve.

3. The sliding device made of low friction material avoids the direct contact between metal and metal.

4. The bottom surface fixed hole, easy to actuator and valve connection and make it right, conform to the ISO5211/DIN3337 standard.

5. The bottom assembly hole is square, easy to connect with the valve stem, and can rotate 45 degrees corner installation.

6. Rotation angle: double action =90 degrees, single acting =90 degrees, from both ends adjustable angle + 5 degrees.

7. Working environment temperature: -20, ~80 degrees.

8. Air source: filter, dry or refueling lubrication of clean air, minimum pressure 0.1Mpa, maximum pressure 1Mpa.

9. Basic design: pneumatic double cylinder, double piston shifting fork drive mechanism. Model AW= double acting; model AWS= single acting type (spring reset).

10. The AW series pneumatic devices are suitable for valves with 1/4 turning (90 rpm). Such as ball valve, butterfly valve, plug valve and so on. The design and manufacture of this product adopt JIS standard, and adopt the international standard ISO5211 with the valve connection department.

AW pneumatic actuator series function:

Double acting pneumatic actuator: two position control of valve opening and closing.

Spring reset: when the circuit is broken or broken, the valve opens or closes automatically.

Single electronically controlled solenoid valve: power supply valve open or closed, when the power off, the valve closed or open (can provide explosion-proof).

Double electronically controlled solenoid valve: one coil to power, the valve open, and the other coil to power, the valve closed, there is memory function (can provide explosion-proof type).

Limit switch back detector: signal that transmits the switch position of the valve remotely (can provide explosion proof type).

Electrical positioner: according to the current signal (standard 4-20mA) size of the valve medium flow adjustment control (can provide explosion-proof type).

Electrical converter: converts the current signal to an air pressure signal, which is used in conjunction with the pneumatic positioner (to provide an explosion proof type).

Air source treatment of triple parts: including air pressure reducing valve, filter, oil mist, the gas supply voltage, cleaning and moving parts lubrication.

Manual operating mechanism: automatic control can be operated manually under abnormal conditions.

AW pneumatic actuator series for use:

The use of AW pneumatic actuator, first determine the valve torque, considering the pipeline medium; water vapor or non lubricating medium increases 25% security value; non lubricated dry gas medium increases 60% security value; powder medium non lubricated gas transmission increases 100% security value; for cleaning, lubrication friction free medium a 20% increase in security value, then according to the source of work pressure, find the double action or single acting type torque meter, can get accurate actuator model.

Pneumatic actuator and valve installation accuracy is correct, and directly affect the safe operation and service life of the actuator. The reasonable installation is that the center shaft of the actuator and the valve stem must be absolutely coaxial and properly connected and installed. Before the actuator and valve are assembled, the torque shall be measured and shall not exceed the required torque. After the assembly, the pneumatic actuator and the wide doors at the same time test, the valve rated pressure to seal pressure, actuator to supply pressure of 4~8bar or according to user needs to switch the intake air pressure, the two inlet pneumatic actuator, pneumatic open and close observation of the situation of the valve, should not stop, the crawling phenomenon, should switch flexible smooth rotation, to repeat trials.

AEN.TECH

AEN.TECH