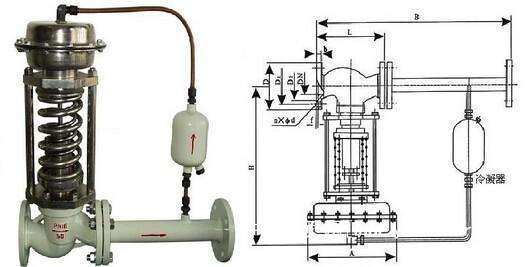

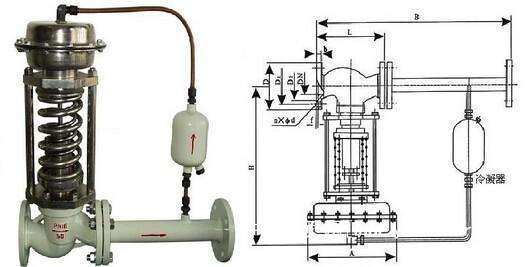

The self-operated pressure control valve does not need external energy, and uses the energy of the medium to be adjusted as the power source, introduces the actuator to control the position of the spool, and changes the pressure difference and flow at both ends to stabilize the pressure before the valve (or after the valve). It has the advantages of sensitive action, good sealing performance and small fluctuation of pressure set point. It is widely used in the automatic control of gas, liquid and vapor medium decompression regulation or pressure relief.

This series of products has three structures: single seat (ZZYP), sleeve (ZZYM) and double seat (ZZYN); the actuator has two types: diaphragm type and piston type; the type of operation has pressure reducing valve pressure adjustment (type B) And pre-valve pressure adjustment (K type). The product's nominal pressure rating is PN16, 40, 64; the valve body diameter range is DN20~300; the leakage level has II, IV and VI grades; the flow characteristics are fast opening; the pressure section is adjusted from 15 to 2500 kPa. Can be combined as needed to meet user requirements.

(1) The self-operated pressure regulating valve can work in a place without electricity and gas without the need of external energy, which is convenient and saves energy.

(2) The pressure segmentation range is fine and crosses each other, and the adjustment accuracy is high, and the pressure set value can be continuously set during operation.

(3) For post-valve pressure regulation, the ratio of pre-valve pressure to post-valve pressure is 10:1~10:8.

(4) Rubber diaphragm type detection, the actuator has high detection accuracy and sensitive action.

(5) The pressure balance mechanism is adopted to make the control valve sensitive and precise.

Main component materials

Valve body: ZG230-450, ZG1Cr18Ni9Ti, ZGOCr18Ni12M02Ti

Spool: 1Cr18Ni9Ti, 0Cr18Ni12M02Ti

Seat: 1Cr18Ni9Ti, 0Cr18Ni12M02Ti

Valve stem: 1Cr18Ni9Ti, 0Cr18Ni12M02Ti

Membrane cover: A3, A3 steel coated with tetrafluoroethylene, stainless steel

Filler: polytetrafluoroethylene, flexible graphite

Rubber diaphragm: butyl, ethylene, propylene, fluorine, oil resistant rubber

AEN.TECH

AEN.TECH