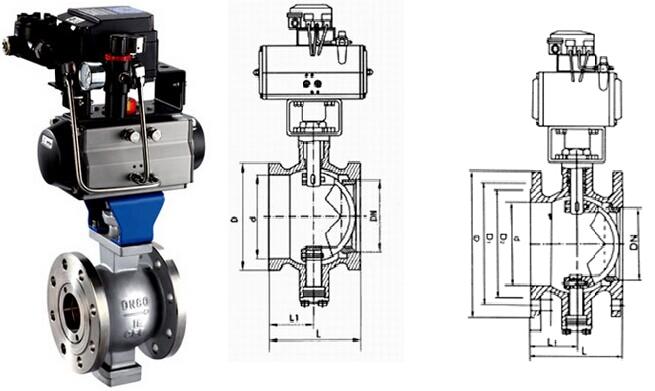

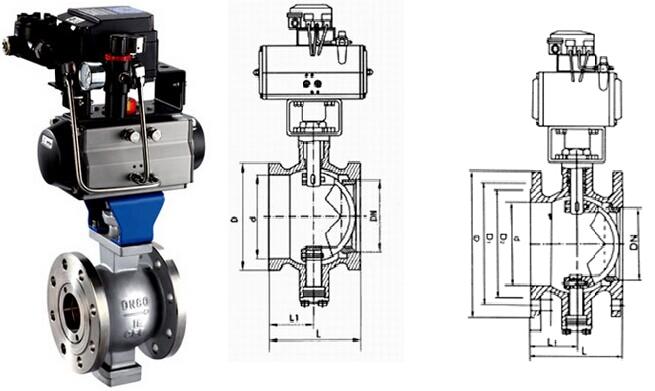

Product overview of pneumatic v - ball valve

High-level control valve with a right-angle rotary structure, which is matched with a valve positioner and can realize proportional adjustment. It can be used in combination with two-position five-way solenoid valve and control box to realize switch control. The valve core of the pneumatic v - shaped ball valve is designed with a v - shaped notch with precise physical properties and control functions. it is suitable for various control occasions. it has the advantages of compact structure, small volume, and can be installed tightly and horizontally. Pneumatic v - shaped regulating ball valve is suitable for controlling gas, liquid and solid granular media. Since there is no gap between the valve core and the valve seat, it has great shear force and self-cleaning performance, and is especially suitable for the control of suspensions and solid particles containing fibers or small solid particles. Therefore, the pneumatic v - ball valve can be widely used in automatic control systems of petroleum, chemical industry, paper making, chemical fiber, electric power, metallurgy, pharmacy, environmental protection and other industrial departments.

( 1 ) pneumatic v - ball valve consists of pneumatic v - ball valve body, pneumatic actuator and other accessories. It is an advanced control valve with a right-angle rotary structure. The v - ball valve does not need repair for a long time and has a long service life. it provides you with a valve that can control the technological conditions with real high efficiency.

( 2 ) excellent regulation characteristics: the pneumatic v - ball valve has an approximately equal percentage of inherent flow characteristics and an adjustable ratio of up to 300: 1. Therefore, the pneumatic v - ball valve can provide accurate control over a wide range of changes.

( 3 ) maximum flow volume: due to its streamlined shape and full right-angle rotation control, the maximum volume is especially high, the passing capacity is especially large, and the flow resistance is small, so smaller, more economical and practical valve sizes can be used.

( 4 ) the pneumatic v - ball valve adopts a double bearing structure, which has high mechanical stability and small starting torque, thus ensuring that the valve has excellent sensitivity and induction speed.

( 5 ) maximum reliability ( safety ): the valve body is of an integral structure and is durable. the operation is not affected by pipeline pressure and leakage of the valve body can be avoided.

( 6 ) superior sealing performance of metal valve seat: pneumatic v - shaped ball valve uses movable metal valve seat, which has compensation aid function, superior sealing performance and long service life. In the direction of flow, the leakage is 10 rated flow coefficient.

( 7 ) super shear capacity: pneumatic v - ball valve adopts metal hard seal structure. during the rotation of pneumatic v - ball valve core and metal valve seat, a strong shear force generated by v - notch and valve seat can cut off fiber and other impurities, and has self-cleaning function, thus preventing valve from sticking.

( 8 ) the pneumatic v - ball valve is compact in structure, compact and lightweight, convenient to install, and easy to maintain.

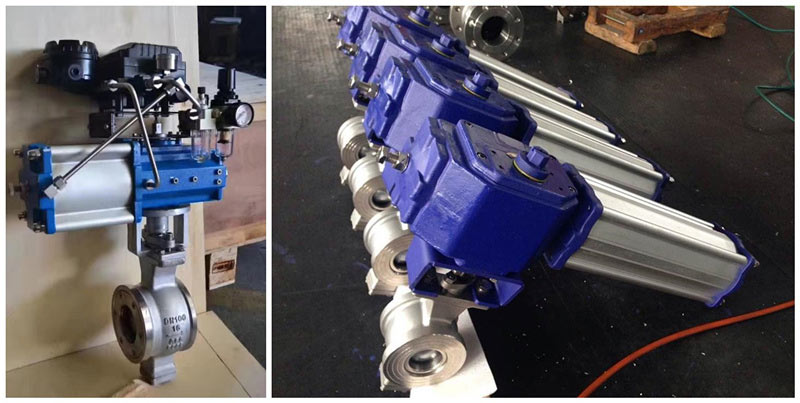

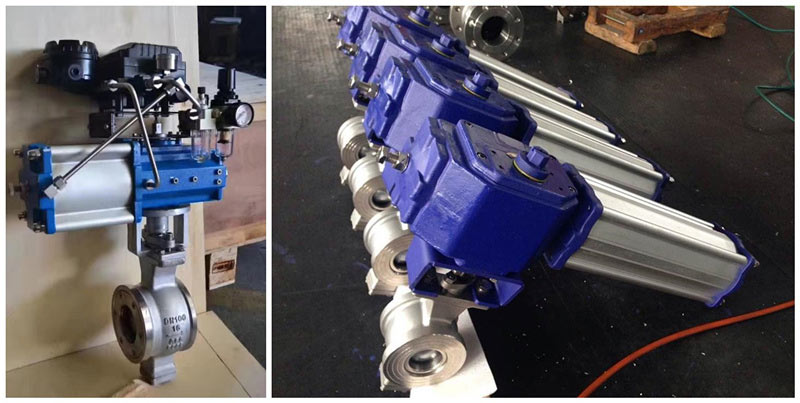

( 9 ) pneumatic actuators adopts piston cylinder and crank arm conversion structure, with large output torque and small volume. The actuator adopts a fully sealed waterproof design and has a high level of protection. The cylinder block adopts an imported mirror cylinder, which has no oil lubrication, small friction coefficient, corrosion resistance, super durability and reliability. All drive bearings are lubricated with boundary self-lubricating bearings without oil to ensure that the transmission shaft is not damaged.

Main technical parameters and performance of pneumatic v - ball valve

| Nominal size DN |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

Rate discharge

coefficient Cv |

32 |

43 |

78 |

90 |

160 |

250 |

360 |

610 |

1120 |

1850 |

2950 |

3700 |

7195 |

11466 |

| Nominal pressure |

PN1.6、2.5、4.0、6.4MPa |

| Strength test |

2.4~9.6MPa |

| Pressure test |

1.76~7.0MPa |

| Discharge characteristic |

Approximately equal percentage |

plate angle (

degrees ) |

0°~90°(adjustable) |

| Allowable leakage level |

Soft seal: zero leakage hard seal: ≤ ratedCv×0.001% |

Soft seal: VI micro bubble level, metal seal: ≤ rated cv x 0.065 % |

| Action time ( s / 90 degrees ) |

8.5~30 |

36~60 |

| Adjustable ratio |

250:1 |

300:1 |

| Configure actuator |

Gt, Sr, ST, at, aw series single and double acting pneumatic actuators |

| Control mode |

Switch type ( switch two-position control ), regulating type ( 4 ~ 20ma control ) |

Technical parameters of pneumatic v - ball valve actuator

| Actuator model |

Gt, Sr, ST, at, aw series single and double acting pneumatic actuators |

| Supply pressure |

0.4~0.7MPa |

| Air source interface |

G1/4"、G1/8"、G3/8"、G1/2" |

| Ambient temperature |

-30~+70℃ |

| Action form |

Single acting actuator: air shutoff type ( B ) - valve position open (FO ) when air is lost; Air opening ( K ) - valve position closing (FC ) in case of air loss Double - acting actuator: air shutoff type (B) - valve position maintenance (FL ) in case of air loss; Air open type ( K ) - valve position maintenance during air loss ( FL) |

| Accessory |

Positioner, solenoid valve, air filter pressure reducer, retaining valve, travel switch, valve position transmitter, handwheel mechanism, etc. |

Adopts a new series of pneumatic actuators, with double-acting and single-acting ( spring return ), rack and pinion drive, safe and reliable; Large diameter valves adopt series aw pneumatic actuators fork-pull transmission with reasonable structure and large output torque. they have double-acting and single-acting types.

1. gear type double piston, with large output torque and small volume.

2. the cylinder is made of aluminum-gold material, which is light in weight and beautiful in appearance.

3. manual operating mechanisms can be installed at the top and bottom.

4. rack type connection can adjust opening angle and rated flow.

5. the actuator can choose live signal feedback instructions and various accessories to realize automatic operation.

6. is 05211 standard connection provides convenience for installation and replacement of products.

7. the adjustable joint screws at both ends can make the standard product have an adjustable range of 4 between 0 and 90. Ensure the synchronization accuracy with the valve.

Main design standards for pneumatic v - ball valves

| Design and manufacture |

GB12237-89、API608、API 6D、JPI 7S-48、BS5351、DIN3357 |

| Flange inch |

JB/T74~90、GB9112~9131、HGJ44~76、SH3406、ANSI B16.5、JIS B2212~2214、DIN2543 |

| structure length |

GB12221-89、ANSI B16.10、JIS B2002、NF E29-305、DIN3202 |

| Inspection and test |

JB/T 9092、API 598、GB/T13927 |

Main parts and materials of pneumatic v - ball valve

| Nominal sizemm |

DN15-DN300 |

| Material code |

C |

P |

R |

| major parts |

Body |

WCB |

ZG1Cr18Ni9Ti |

ZG1Cr18Ni 12Mo2Ti |

| Ball |

2Cr13 |

1Cr18Ni9Ti |

1Cr18Ni12MoTi |

| Stem |

2Cr13 |

1Cr18Ni9Ti |

1Cr18Ni12MoTi |

| Seal ring |

Reinforced PTFE para-polystyrene |

| paking |

PTFE flexible graphite |

Applicable

working

condition |

Applicable medium |

Steam, water, oil |

Acetic acid |

Applicable

temperature |

-28℃ - 300℃ |

Main performance specifications for pneumatic v - ball valves

| Nominal size DN(mm) |

DN15-300 |

Nominal

pressure |

PN(MPa) |

1.0 |

1.6 |

2.5 |

4.0 |

6.4 |

| Test pressure |

Strength test |

1.5 |

2.4 |

3.75 |

6.0 |

9.60 |

| Pressure test |

1.1 |

1.76 |

2.75 |

4.4 |

7.04 |

Low pressure

airtight test |

0.5~0.7 |

Applicable

medium |

Water, oil, steam, nitric acid ( temperature ≤ 200 ℃ ), acetic acid ( temperature ≤ 200 ℃ ) |

Product selection of pneumatic v - ball valve

( 1 ) valve body parameters: nominal diameter, working pressure, process medium, use occasion, valve body material and other series of parameters.

( 2 ) actuator parameters: actuator form, control mode, control signal ( 4 - 20ma, 1 - 5v ), action mode ( air - open, air - closed )Provide the above technical parameters in detail as far as possible, so as to facilitate our company's operation and technical personnel to accurately select the type for you. If you have any questions, you can call us and we will do our best to provide you with quality service!

AEN.TECH

AEN.TECH