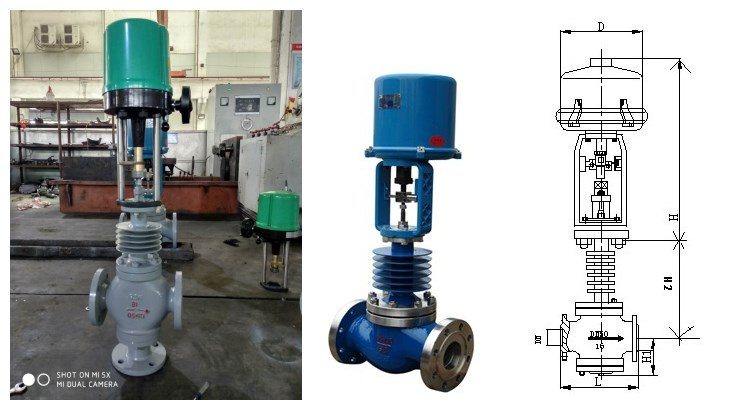

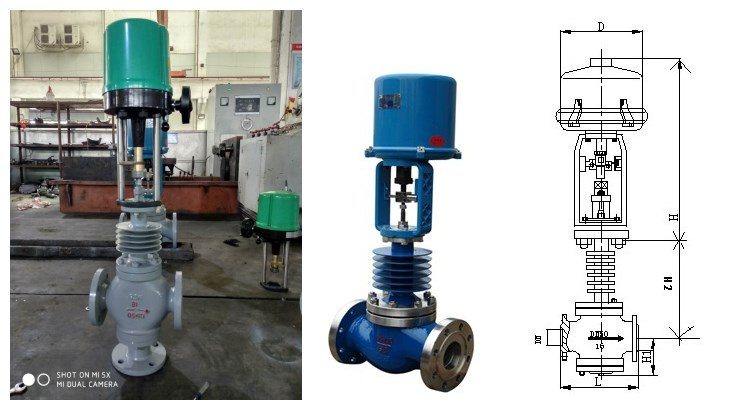

Electric high temperature control valve product description

Electric high temperature control valve is composed of intelligent integrated actuator and high precision low flow resistance control valve body. The electric high-temperature control valve has the advantages of tight closing, compact structure, light weight, and convenient maintenance. The electric high-temperature control valve is composed of a 3810 series Electric Actuator and a small-sized regulating valve body. It includes a feeding function and accepts a uniform 4-20mAor1-5V.DC standard signal to convert the current signal into a phase. The corresponding straight line displacement automatically controls the opening of the regulating valve to achieve continuous adjustment of the process parameters such as the pressure, flow rate, temperature, and liquid level of the fluid in the pipeline. The electric high temperature regulating valve adjusting mechanism adopts the balanced valve plug structure. The electronic electric high temperature regulating valve has the characteristics of good valve stability, low vibration, low noise, small temperature-sensitive characteristics, and allowable use pressure difference and large temperature. Electric high-temperature control valve is widely used in occasions where the flow rate is large, the temperature is high, and the leakage amount is not strict. Widely used in gas, liquid, steam, oil and other corrosion characteristics of the media in the pipeline automation control.

AEN.TECH

AEN.TECH