AEN All

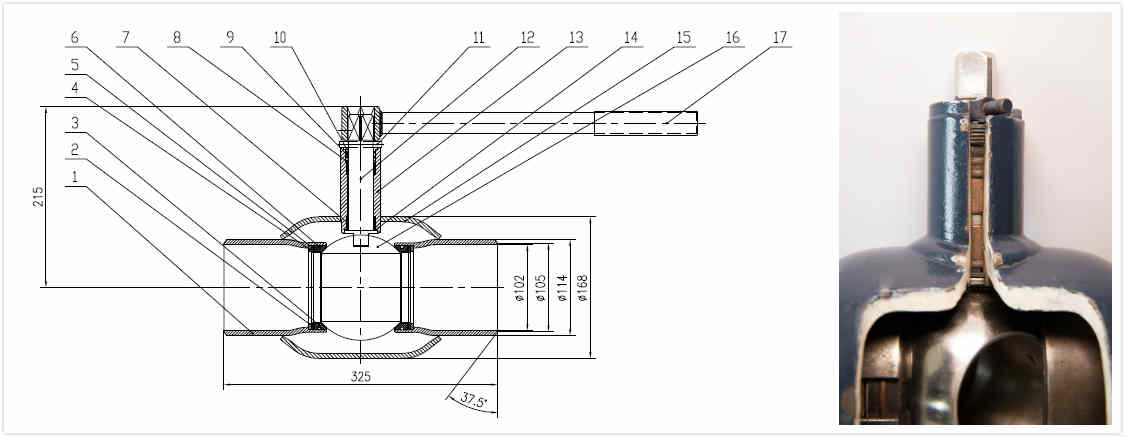

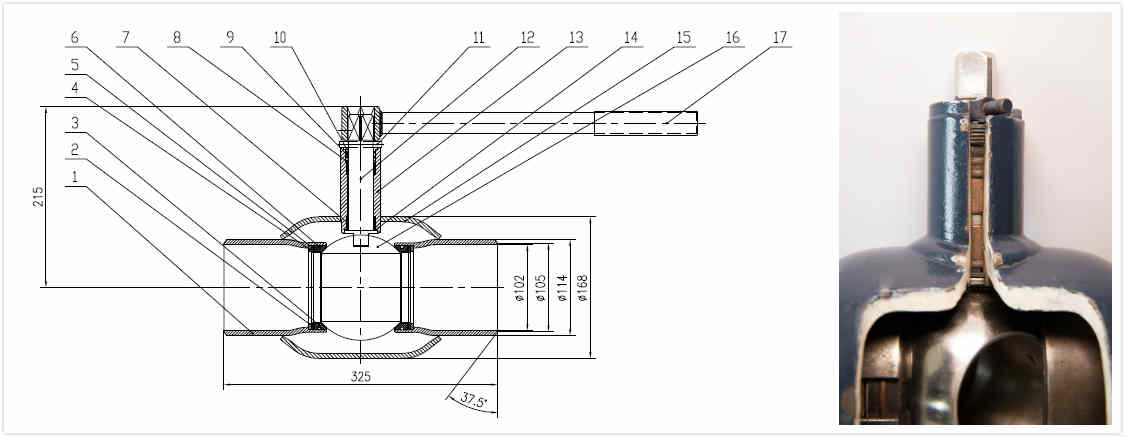

welded ball valve structure features:

1、15 High-quality valve body seamless steel pipe,

quality assurance;

2- High-quality valve seat seal unit, which strictly controls the

quality of the seal and guarantees no leakage under long-term working

conditions;

3-6 Imported pre-tightening unit guarantees even force of valve core

during pre-assembly and effective compensation under long-term use conditions;

7-8 Double-slide bearings ensure the rotation of the valve stem in the

valve sleeve, anti-locking and effectively guarantee the assembly accuracy and

reduce the torque;

9-11、14 Stem seal unit, multi-level combination type

adjustable seal, to ensure that the valve will not leak under long-term use

conditions, stem torque can be adjusted according to site use and requirements;

12 Stem, tempered 304 stainless steel, to ensure long-term use does not

rust, corrosion resistance, improve material strength after quenching and

tempering, to ensure that in the case of long-term high torque, no deformation,

no fracture, smooth movement, easy to switch;

13 Stem sleeve, stepped seal unit machining parts, guarantee stem

strength, provide effective support and seal;

16 Ball, tempered 304 stainless steel, ensure long-term use does not

rust, corrosion resistance, improve the material strength after quenching and

tempering, to ensure that in the long-term high-torque conditions, no

deformation, no fracture, smooth movement, switch freely;

AEN.TECH

AEN.TECH